Bitumen Bag Decanter VS Bitumen Drum Decanter

Bitumen bag decanters and bitumen drum decanters vary in several aspects, such as their working principles, structural designs, heating methods, melting capacities, and application scenarios. The choice between the two depends on various factors such as the type of bitumen packaging used and the specific requirements of your asphalt production process.

How do they operate? What are the differences between them? What factors should be considered when purchasing bitumen melting machine in China? This article will give you all the answers.

CONTENTS

Things You Should Know About Bitumen Decanter

Bitumen decanter is a specialized machine specifically built to heat up and liquefy solid bitumen. It comes in two main types: drum and bag varieties. With this machine, bitumen can reach a ideal consistency that allows for easy extraction from drums or bags by heating the bitumen in its chamber to a specific temperature. Finally, the molten bitumen is then pumped out for use in further construction or storage processes.

The temperature of decanted bitumen is typically between 120°C and 180°C. During the heating and transportation stages, bitumen temperature is maintained within the range of 150°C~170°C, while bitumen is generally kept between 140°C and 160°C in road construction applications.

What Is a Bitumen Drum Decanter?

A bitumen drum decanter is a workhorse that tackles drummed bitumen, heating and processing it to meet the exact specifications needed for the next stage of the project.

The equipment mainly consists of decanting chamber, lifting mechanism, heating system, melting chamber and electrical control system.

Bitumen Drum Decanter Working Steps:

- Step 1 Push bitumen drums into the decanting chamber using lifting machinery and hydraulic pushers, where they will be heated.

- Step 2 After bitumen becomes a viscous liquid, it flows into the melting chamber where it is mixed and broken down under the action of rotation and stirring, during which impurities are removed.

- Step 3 Finally, keep heating bitumen to a viscosity suitable for pumping, and then pump it out.

The majority of bitumen drum decanter machines currently available on the market have a production capacity ranging from 5t/h to 10t/h. Those with larger specifications or advanced technologies may have higher capacities.

Model: DJT-5000

Bitumen Storage Volume: 5t/h

Quantity of Barrels/Cycle: 15

Bitumen Pump Flow Rate: 25m³/h

Number of Tracks: 2

Bitumen Temperature: 120℃

Method of Loading Barrels: Cylinder

L×W×H: 9,000×2,250×2,500mm

Working Voltage: 380V

Total Power: 7.5kW

Total Weight: 11,000kg

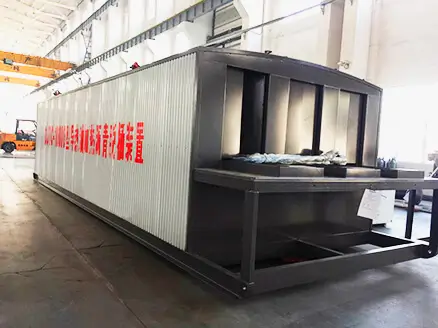

What Is a Bitumen Bag Decanter?

Bitumen bag decanter, also known as a big bag asphalt melting machine, is a specialized piece of equipment designed to efficiently melt solid bitumen delivered in large, one-ton bags.

It is mainly consisting of lifting device, conveying system, heating system, melting chamber and electrical control system.

Bitumen Bag Decanter Working Steps:

- Step 1 Feed bagged raw bitumen into the heating area using the lifting device and conveying system after opening the bag.

- Step 2 Gradually melt bitumen using a thermal oil heating system, during which impurities are separated.

- Step 3 Melted bitumen is then transported to the melting chamber where it undergoes further intense heating via fire tubes until the pumping temperature is reached, at which point it is pumped out.

Depending on the model, the production capacity of bitumen bag decanters reaches over 8 t/h.

Model: LTD-8

Feeding Ports: 3

Hoisting Capacity: Maximum lifting weight 2T

Hoisting Height: 3m

Bitumen Pump Flow Rate: ≧24m³/h

Melting Capacity: ≧6t/h

Dimention of Hoisting Unit: 12×2.2×4m

Dimention of Heating Chamber: 9.1×2×2m

Thermal Insulation: 50mm rock wool plus sheet

Feeding Port Size: 1.4×1.6m

Insulation Materials: 50mm rock wool plus plate

Differences Between Bitumen Bag Decanter and Bitumen Drum Decanter

Bitumen bag decanter machine and bitumen drum decanter machine are used to process raw bitumen, remove impurities and convert it into a liquid form that is convenient for use. Both of these two types are equipped with an automatic electronic control system to ensure safe and stable operation. However, differences exist as a result of their different working principles:

1. Functions

The two types of decanters process materials of different packing form. Bitumen drum decanter machines are primarily used to heat and extract bitumen from drums, while bitumen bag decanters are mainly used to process bagged bitumen by melting solid bitumen using a thermal oil heating system.

2. Structure

Bitumen drum decanters consist of components such as a decanting chamber, lifting mechanism, hydraulic propulsion system, melting chamber, oil pipe heating system and electrical control system. The bitumen bag decanting plant, on the other hand, comprises a decanting chamber, lifting device, conveying system, melting chamber, heating system, and a fire tube intensified heating unit.

3. Work Flow

Bitumen drum decanters mainly focus on the degree of mechanical automation, and use advanced mechanical devices to quickly and efficiently extract bitumen from drums, which reduces the labor intensity of workers and improves production efficiency; bitumen bag decanting plant is designed to process a large volume of bitumen in bulk bags and its focus is on the design and optimization of the heating system, with an emphasis on the melting capacity. Bag type uses a thermal oil heating system, combined with a fire tube for enhanced heating, which can quickly melt the bagged bitumen into liquid, leading to high production efficiency.

4. Production Capacity

The optimization of the heating system gives bitumen bag decanter machinery higher melting efficiency. In cases where the overall dimensions of the bitumen decanting plants are similar, bitumen bag decanters typically present a greater processing capacity. For example, a typical ISO 20FT equipment box can accommodate 20 one-ton bags for heating treatment at a time. On the other hand, drum-packed bitumen is typically 180 kg per drum, and the processing capacity of bag decanter machinery may be limited by the drum size and quantity, potentially resulting in a relatively smaller capacity.

Model: DJT-3000

Bitumen Storage Volume: 3t/h

Quantity of Barrels/Cycle: 14

Bitumen Pump Flow Rate: 25m³/h

Number of Tracks: 2

Bitumen Temperature: 120℃

Method of Loading Barrels: Cylinder

L×W×H: 7,550×2,250×2,500mm

Working Voltage: 380V

Total Power: 7.5kW

Total Weight: 10,000kg

5. Energy Saving and Environment Protection

Bitumen bag decanters often adopt an enclosed structure, which effectively reduces the volatilization and leakage of bitumen during the decanting process, thereby reducing environmental pollution. Additionally, some advanced bitumen bag decanting plants are equipped with an efficient heating and circulation system, which reduces energy consumption and may be somehow advantageous in energy-saving and environmental protection. Bitumen drum decanters also have their own characteristics on energy conservation and environmental protection. Their enclosed production structures significantly reduce environmental pollution. Furthermore, drum type typically uses advanced heating and control systems, improving energy utilization efficiency. Therefore, both types of bitumen decanting machinery have their own unique.

In general, the two types have different application scenarios and advantages in the bitumen processing and treatment process.

| Feature | Bitumen Drum Decanter | Bitumen Bag Decanter |

|---|---|---|

| Raw Material | Drums (Various specifications) | Bags (Various specifications) |

| Automation | High | High |

| Unloading | Fast, enclosed, pollution-free | Automated, continuous |

| Flexibility | Lower | Higher (Processes different bag sizes/weights) |

| Melting | Highly efficient | Highly efficient |

| Processing Capacity | Often lower(5t/h ~ 10t/h) | Often larger(over 8t/h) |

Explore Pricing Options for Bitumen Melting Machine

What Factors Should Be Considered When Selecting an Asphalt Melter

Bitumen drum decanters and bitumen bag decanters have their own advantages. When customers are selecting a decanter machine to purchase, it is recommended to consider the following:

1. Production Needs

Production needs include the packaging form of bitumen, as well as the desired processing capacity and speed of the bitumen decanter. For large-scale production that requires the processing a significant volume of bitumen, such as in road construction, bitumen bag decanting plant, may be a more suitable choice. For smaller bitumen requirements, where the quality and application range of bitumen are more demanding or environmental regulations are stricter, such as in waterproofing, anti-corrosion, or other industrial applications, bitumen drum decanter machinery are more appropriate.

2. Outline Dimensions

20FT and 40FT containers are widely used in international shipping. Therefore, choosing a bitumen melter in dimensions that are more suitable for international shipping saves transportation costs.

3. Service Life

To select a bitumen decanter that best suits needs, users should comprehensively consider factors such as make, quality, price, after-sales service, performance and service life, whilst carefully evaluating the cost-benefit ratio when selecting a bitumen decanting plant.

Find Your Ideal Bitumen Decanter

Summary

Both bitumen drum decanters and bitumen bag decanters play an irreplaceable role in the bitumen processing industry with their unique features. Their respective characteristics and advantages allow customers to select the most suitable bitumen decanting plant based on production requirements, thereby improving production efficiency, reducing production costs, and contributing to the sustainable development of the bitumen processing industry.